What’s the Real Cost of a Configuration Error?

At first glance, configuration errors seem harmless—just incorrect selections, wrong dimensions, or mismatched components that can be corrected. But the real cost of configuration errors is often invisible until damage, delays, or customer fallout occurs.

Manufacturers usually invest in CPQ to speed up quoting or reduce expert dependency. While true, the bigger value lies in risk elimination:

- Preventing catastrophic errors

- Ensuring every specification meets application requirements

- Eliminating rework costs from inaccurate quotes

- Protecting customer trust and brand reputation

When a configuration error slips through, the financial impact stretches far beyond the cost of fixing the issue.

What Are the Three Components of the True Cost of Error?

1. Direct Costs (Immediate, Visible Losses)

These include:

- Rework and scrap

- Incorrect BOMs

- Rush shipping

- Field service calls

- Warranty replacements

- Production downtime

This is where most businesses think the cost ends.

2. Indirect Costs (Hidden Losses)

These are often far greater:

- Engineering time spent correcting mistakes

- Delayed orders and extended lead times

- Penalties for missed delivery commitments

- Lost productivity across departments

- Extra coordination between sales, engineering, and manufacturing

Indirect costs typically outweigh direct costs by 2–5x.

3. Opportunity Costs (The Most Expensive Losses)

This is where the real damage happens:

- Loss of customer trust

- Repeat sales that never happen

- Negative references and reputational harm

- Impact on future bids

- Increased churn

- Lower win rate due to perceived unreliability

Most manufacturers never calculate these—but these are the losses that have been compounded over the years.

Understanding the Risk: Real-World Lessons from Configuration Failures

Your original stories have been restructured for clarity and impact.

1. Highly Flammable Eichler Homes — When Materials Go Wrong

Eichler homes, built with oil-stained mahogany walls, became infamous because once a fire started, the home would burn down within minutes. The choice of materials—a configuration decision—created catastrophic risk.

Lesson:

In manufacturing, material selection rules must be enforced. A CPQ system embeds safety, compliance, and code requirements directly into configuration logic—preventing selections that introduce liability.

2. Hyatt Regency Walkway Collapse — The Deadliest Structural Engineering Error

A seemingly small design modification to the hanger rod configuration caused the walkways inside the Hyatt Regency Kansas City hotel to collapse.

Result: 114 deaths, 214 injuries, lawsuits, and millions in damages.

Lesson:

Configuration changes require validation. CPQ enforces approval workflows, weight limits, load capacities, and rule-based restrictions that prevent unapproved substitutions.

3. NASA Mars Climate Orbiter — A Unit Conversion Disaster

NASA lost a $125 million orbiter because of mixed units:

- English units (pounds)

- Metric units (Newtons)

One configuration mismatch destroyed the entire mission.

Lesson:

CPQ prevents incompatible units, mismatched measurements, and invalid combinations—ensuring only one consistent standards system is used.

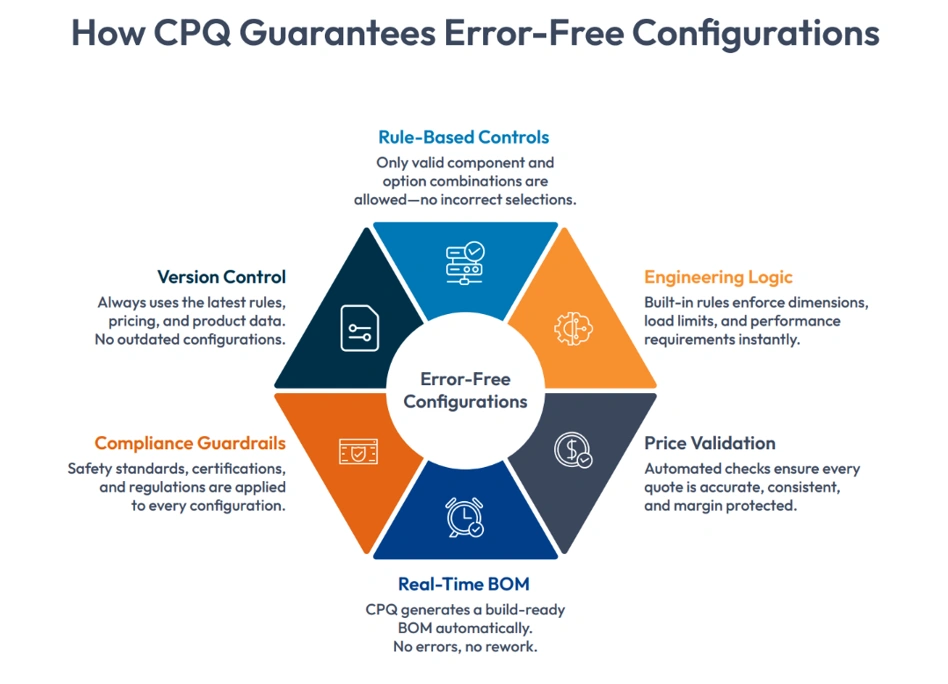

How Does CPQ Guarantee Error-Free Configurations?

A modern CPQ system eliminates the root causes of configuration mistakes:

1. Rule-Based Configuration Controls

Only valid combinations, components, and materials can be selected.

2. Embedded Engineering Logic

Engineering constraints (dimensions, load limits, performance specs) are enforced automatically.

3. Automated Price Validation

Prevents inaccurate quotes, margin leakage, and pricing inconsistencies.

4. Real-Time BOM Creation

Ensures manufacturing receives accurate, buildable data every time.

5. Compliance & Safety Enforcement

Standards, certifications, and regulations are baked into configuration rules.

6. Version & Change Control

No outdated rules. No old price books. No expired product versions.

Outcome: CPQ eliminates the hidden costs of manual quoting and reduces configuration error rates to almost zero.

What Is the Hidden Cost of Lost Customer Trust from Quoting Errors?

When a bad configuration reaches a customer, the impact is immediate:

- Loss of confidence in your technical expertise

- Delayed onboarding or deployment

- Higher churn risk

- Reduced upsell/cross-sell potential

- Lower lifetime customer value

Trust lost to configuration errors is extremely difficult to regain.

Customers expect:

- Accuracy

- Responsiveness

- Expertise

- Reliability

A single quoting error can permanently shift customer perception.

What Is the ROI of Preventing Configuration Errors with CPQ?

Manufacturers using CPQ report measurable ROI across several areas:

1. Lower Rework Costs

Up to 40–60% reduction due to error-free BOMs and configurations.

2. Faster Quote-to-Order Cycles

Quotes go out 5x faster, increasing win rates.

3. Higher Margin Protection

There are no accidental discounts, pricing overrides, or missed charges.

4. Reduced Engineering Dependency

Engineering review time can drop 30–50%.

5. Fewer Order Returns or Field Fixes

With valid configurations, returns drop and service issues decrease.

6. Customer Trust = Repeat Revenue

Prevention of quoting errors directly increases lifetime value.

When you calculate the cost of sales errors, CPQ consistently pays for itself—often within months.

Conclusion

Configuration errors are rarely “small.” They ripple across cost, compliance, customer trust, and long-term revenue. By enforcing accurate, rule-based configurations, CPQ removes the guesswork and prevents the costly mistakes that manual quoting can’t catch. For manufacturers, the message is clear: avoiding a configuration error is far cheaper—and far safer—than correcting one. With CPQ, every quote becomes accurate, compliant, and confidence-building.

FAQs

1. What causes most configuration errors?

Manual quoting, inconsistent rules, outdated spreadsheets, and lack of centralized product data.

2. How does CPQ prevent configuration mistakes?

Through rule-based configuration, automated validation, accurate pricing logic, and real-time data sync with ERP/CRM systems.

3. What industries face the highest risk of configuration errors?

Medical devices, engineered products, specialty vehicles, industrial equipment, and any sector with complex assemblies or regulatory requirements.

4. Can CPQ reduce rework and warranty costs?

Yes. Eliminating misconfigurations significantly lowers rework, scrap, service calls, and warranty claims.

5. What is the financial impact of quoting errors?

They affect revenue, margins, engineering time, delivery timelines, and customer trust—often costing 10–20x more than direct correction costs.